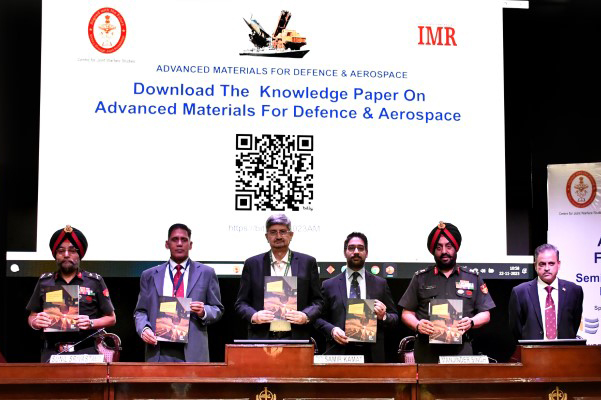

Indian Military Review (IMR), in collaboration with the Centre for Joint Warfare Studies (CENJOWS), organised a seminar & exhibition on “Advanced Materials for Defence & Aerospace” on 22 November, 2023 at New Delhi. Prominent panellists in the seminar included senior serving members from tri-Services, DRDO scientists, IIT and industry. The seminar offered an environment for the industry to interact with the armed forces and engage in sharing of knowledge along with expectations of the user. The seminar was conducted in five sessions.

SESSION 1: INAUGURAL SESSION

Opening Remarks. Lt Gen Sunil Srivastava, Director CENJOWS, emphasized on the importance of critical and advanced materials and its supply chain across the continents and how the recent conflicts in Europe and Middle East had affected the availability of special materials. He highlighted importance of advanced materials in weapon platforms to achieve the asymmetric advantage over our adversaries. Nano-materials, meta-materials, multifunction materials, and biomimetic materials are all smart materials which are being leveraged to have supremacy in the battlefield. Countries like United States, Australia, France, Germany, Japan, have got critical material strategies and policies. We are still yet to announce a critical materials strategy or policy.

Our country spent close to $2 billion worth of imports of advanced materials every year and majority of this comes from a potential adversary which is an issue of great concern. We have indigenized most of our systems but the special materials for these systems are being imported. We need to be conscious as to how we get self-reliant for semiconductors and critical material. The Mineral Policy of 2020, has already assured a lot of corrective policy measures. The Mines and Minerals Development and Regulations (MMDR) Act of 1957, has been amended twice recently as a result 30 critical minerals have been identified and opened up for auction to the private sector. Even Lithium has now been deregulated. For global partnerships, India is now engaged with the outside world through Initiative on Critical and Emerging Technologies (ICET) with the United States. India has also signed the Mineral Security Partnership in 2023, with the US and 12 other entities including EU. India has also inked a Critical Mineral Investment Partnership with Australia. It has signed MOUs to engage with Chile, Argentina, Australia on getting Lithium, Cobalt and other special metals and to translate this into action, all the stakeholders were expected to brainstorm the issues.

Keynote Address. Dr Samir V Kamat, Secretary Dept of Defence R&D & Chairman DRDO, emphasized that to have significant improvement in the performance of the defence systems, better materials with superior manufacturing technologies were required to be put in place. Unfortunately, we have not paid much attention to this important field. If we want to achieve our prime minister’s dream of Atmanirbhar Bharat and technology leadership in this Amrit Kaal, we have to pay greater attention to this stream of technology.

Broadly, materials can be divided into structural and functional materials, based on their roles. There are materials which perform the load bearing task for any weapon platform and there are materials which perform certain functional role of specific nature. Structural materials are materials such as steels, aluminum alloys, titanium alloys, polymer matrix composites, ceramic matrix composites. Functional materials are semiconductors, silicon, gallium arsenide, gallium nitride, permanent magnets and stealth materials.

We have been fairly strong in the structural materials. However, manufacturing of functional materials remains a grey area for us. We were left behind in the Silicon race in the 70s. For the new semiconductor materials developed for high power electronics such as silicon carbide, we have to ensure that we do not miss the opportunity. If we want to design hypersonic missiles, we need to first develop the scramjet propulsion and to develop scramjet propulsion, we need to develop materials which can withstand those high temperatures. To achieve that we need to look at niobium alloys, and nickel based super alloys with cooling channels.

Developing materials for defence and aerospace has several challenges. Some of these challenges are low volume and sporadic orders for the industries, stringent requirements for qualification and certification exponentially increasing the overall cost. However, the most significant challenge is the long development cycle for any material development. The design cycles for new weapon systems are shrinking. They are now down to about 4 to 5 years where as the new material development cycle is 10 to 15 years. So it is extremely challenging for a designer to starts designing a system to decide which material he should use. Lots of attempts internationally are now being made to see how this new material development cycle can be shrunk. Efforts are being made and over the next 10-15 years, we will be able to make some progress in lot of fields. The other initiative which is happening globally is known as the materials genome initiative which is a more hybrid approach.

It is the materials modelling approach including rapid experimentation approach and also using artificial intelligence and machine learning approach. Lot of material data has been collected over the years and using AI-ML tools. It is possible to get some insight into what should be a material or what should be the composition of a material or what processing should be used to achieve the desired outcome. As a nation we must have a more collaborative approach where academia, R&D institutions as well as industry work together to achieve this goal. The challenges start when we have to scale up from laboratory to industrial scale. The challenges are not only technical in nature but also techno commercial because unless the volumes are large, the cost becomes high. The issue of the infrastructure required for materials manufacturing is also very costly.

Theme Address. Lt. Gen Manjinder Singh, DCIDS (PP&FD), HQ IDS highlighted the overwhelming reliance on China for critical hardware and special materials. The inclusion of fabrication and production of semiconductors through the new semiconductor policy was a welcome step. Dwelling upon the broad application of 3D printing, additive manufacturing from its initial beginning on a commercial scale, it has come a long way from medical equipment to space. The recalled Deng Xiaoping’s remarks about crude oil being synonyms with the Gulf and rare earth elements to China. ICT industry was seeking safer sources for conductors and semiconductors outside China. This is where India stands to gain. The West’s over-independence on China for rare earth elements has exposed the critical fault lines that are now being addressed globally. Tech giants like Apple, Boeing, Lockheed Martin are tightly coupled with China on the relevance of advanced materials, semiconductors and rare earth elements and trying to decouple the same. India must move into the semiconductor space with attractive investments opportunities to create a credible alternative to China’s manufacturing industries. Tata Group’s acquisition of the Bristol plant for manufacturing chips and iPhones in India demonstrates India’s intent to harness the opportunity of decoupling from China.

Modern war demands fighting and winning with indigenous solutions. Adoption through innovation of critical emerging technologies such as advanced materials, rare earth elements, composites and semiconductors are the way forward for our nation and to achieve this public, private sector industries, academia, and defence forces needs to collaborate frequently at all echelons. The government is putting policy and procurement measures in place, requisite hand-holding of industry, exploring this space is need of the hour for capability building and obviating foreign dependencies in this field.

Special Address. Maj Gen Charanjit Singh Mann, Additional DG Army Design Bureau highlighted the perspective of a user. He mentioned that the quality, type and composition of materials is insignificant for the user. What matters to the soldier is that it should be able to perform the desired task. He highlighted the kinds of advanced materials which are required for land forces applications. He mentioned about the importance of higher strength to weight ratio because it leads to overall weight reduction for the soldier’s equipment and weapons. He also emphasized upon high thermal stability, enhanced electrical conductivity, strength performance, higher sensing capabilities, and energy storage along with, durability factors of the equipment which impacts its overall configuration for fighting a battle. Speaking about each of these parameters he mentioned that land systems should be lightweight, flexible with higher performance to improve the agility for a soldier and afford manoeuvrability to the platform. All efforts should be made to reduce the overall load of a soldier. Even two kgs of helmet is also heavy for him during combat. Similarly, the bullet proof jackets or vests should also be as light and flexible and protective in nature. The materials used in unmanned aerial systems, directed energy weapons like Laser, Microwave systems should be able to withstand high temperatures. Special batteries, which are lightweight and compact are required. Conformal sensors and integrated circuits should be small and light with improved aerodynamic.

The communication systems have to be lightweight high performance antennas. EMI shielding should also have high signal integrity and low loss. Similarly, counter measures systems should also light weight high portability with ability to detect stealthy assets. For example, radar systems equipped with advanced signal processing algorithms and integrated with meta-material based antennas should be able to dissipate the effectiveness of strength materials by unique electromagnetic properties. The requirement of keeping the troops warm at high altitude regions should use materials which can withstand the wear and tear of weather and extreme fluctuation of temperature. With advanced materials we can achieve a much more efficient habitat system. He highlighted certain initiatives, projects which are under consideration, eg, protective spray on coatings and paints, especially for the unmanned aerial systems protecting them from high power laser weapons, the nano caffeine absorber coatings for different kinds of defence applications ceramic protection solution for armor protection, low cost sensor technology to detect different bio-warfare agents, smart thickening, fluid-based, ultra-resilient, adaptive kinematic soft rubber armour, sub-zero temperature Lithium-Ion batteries for supporting high altitude operations, energy harvester assisted power bank for mobile equipment, which shows a comprehensive integration of advanced materials across diverse domains within the defence forces.

Col Kuber highlighted that China had imposed export restrictions on gallium, gallium and germanium in response to American sanctions exposing the vulnerabilities of Western countries on dependence on China for critical raw materials. Turkey does not have certifications, which is time consuming and sometimes frustrating. They follow the supply and demand concept along with user requirements and they are one of the largest exporters of special materials. As far as China’s ambitious Belt Road initiative is concerned, they are proactively engaged with African Union countries and Australia to meet their burgeoning demand. China is diversifying its supply sources by investing in Africa and Australia. India has placed certain materials in the positive list of indigenization, which is highly significant for the industry. Raw materials which are available in India, should be banned for import. Government of India policy on critical minerals declared in June 2023 enables the private players to explore and mine these minerals. This is a defining moment for the industry.

SESSION 2 : ADVANCE MATERIALS FOR AEROSPACE

Session 2 was chaired by Air Vice Marshal Yalla Umesh, Asst Chief of Air Staff (Engineering), Air HQ.

Prof Ravi Shankar Kottada, Dept of Metallurgical & Materials Engineering, IIT-Madras, spoke on Stealth Materials, Components and Technologies for Aero applications. He explained the latest technologies in preparation of special advanced materials. He highlighted that Addictive Manufacturing was the process of joining materials to make parts from 3D model data. Elaborating on these methods he explained the process of Metal Additive Manufacturing (AM) by Laser Powder Bed Fusion (PBF), Direct Energy Deposition (DED), and Sheet Metal Lamination method. Chessboard Strategy results in better properties in alloys.

Srinath Ravichandran, CEO Agnikul Cosmos, covered the essential aspects of Agnibaan, which is an Agnikul’s mini space launch vehicle. The vehicle is dedicated and fully customizable for launching small satellites. It offers a 40 times faster launch turnaround which is a significant improvement in launch scheduling. The vehicle is linearly scalable from carrying 30 kg to 300 kg, indicating cost-effectiveness for various payload sizes which is 10 times cheaper. The Visitors att engines are named Agnite and Agnilet. Each Agnite engine can produce 25kN of thrust at sea level and can be configured with 4, 5, 6, or 7 engines. The Agnilet engine produces 8kN at vacuum. Its first flight was scheduled for Nov or Dec 2023.

Alok Singh Chauhan, Scientist F, DMRL, DRDO, spoke on Superalloy Casting Technologies For Aero Gas Turbine Engine Applications. He included:

- 3D printing as Manufacturing Technique in Aerospace.

- Application of Copper in Aerospace.

- Engine Components.

- Landing Gear Components.

- Electrical Wiring and Connectors.

Covering the canvas of Challenges in 3D printing of Copper & Smart alloys, he brought out issues pertaining to :

- High Thermal Conductivity.

- Oxidation Sensitivity.

- Printability.

- Thermal Stresses and Cracking.

The chairperson concluded by highlighting that all super alloys may not be meant for manufacturing. While super alloys are highly specialized materials known for their exceptional mechanical strength, resistance to thermal creep deformation, good surface stability, and resistance to corrosion or oxidation, they might not always be suitable for use in manufacturing processes.

SESSION: 3 – ADVANCED MATERIALS FOR LAND SYSTEMS, MISSILES AND NAVAL APPLICATIONS

The session was chaired by Rear Adm K Srinivas, Asst Chief of Materials (Dockyard and Refit), Naval HQ. He opened the session by highlighting importance of advance materials in manufacturing of battle ships for the Indian Navy. The Indian Navy uses specific material for ship building, eg, advanced steels for hulls for ships. Materials used for hulls is completely indigenous, highlighting Atamnirbhar Bharat success story. These materials are being developed by DRDO through integral research fraternity. Composite materials used in ship-building to reduce weight and increase stealth features are constantly being improved locally. To highlight self sufficiency of the country in the field and specialisation, it was mentioned that Vizag Dockyard uses 22 different types of steels for various manufacturing activities. Indian Navy’s requirements in future will be met completely through indigenous sources. Research & development by DRDO on fuel cells, coatings, thermal conductors, alloys, etc was also highlighted.

Cdr BK Singh from Directorate of Naval Design, Naval HQ, spoke on Special Materials for Ships and Submarines Building.” He gave information about structural materials used for ships/submarines and the types of materials used – high strength low alloy steels for hulls, Titanium and Cu-Ni alloys for pipes, Aluminum alloys for superstructures, composites materials for hull of small crafts, and cladded steel for interface structure. Covering the canvas of material failure he mentioned that it primarily occurred in the form of fracture/ fatigue/ creep. He emphasised upon the desired strength of materials required and explained factors of yield strength, resistance to brittle fracture, toughened materials and good ability to get welded. He mentioned that constant efforts were being made to develop high strength steel. He spoke about challenges faced in Titanium welding and future development of materials with improved qualities like steels with yield strength of 1000 MPa, metal fiber composites and biometric hull.

Lt Col Kunal Tagunde, Instructor Call A, College of Military Engineering, Pune spoke on Latest Developments in Impact Absorbing Body Armour. He gave the historical perspective, mismatch in requirements versus products in use by troops. He highlighted the aspects of flexibility, ergonomics, latest trends, new and innovative materials being developed, eg, Fiber, CT, Carbon Nano, etc. He briefly covered the Initiatives By CME, Pune on project Padam Kawach.

SESSION 4 : SMART & FUTURE MATERIALS/REAR EARTHS & SEMICONDUCTORS

The session was chaired by Rear Admiral (Prof) Deepak Bansal, IIT-Madras. He highlighted the need to devise a strategy to develop an ecosystem related to chips as well as special materials by bringing together all stakeholders including the Govt. He mentioned that Rare Earths are in abundance, however, these oxidised materials are rare because most deposits are of low in concentration and takes lot of efforts to process them.

Anuttam Mishra, Director (Technical), Indian Rare Earths Ltd spoke on Smart and Future Materials and Rare Earths. He recounted efforts of DAE in last 40 years. He said that rare earths were a group of 17 chemical elements which were used to produce useful high-tech products. Seven minerals are available in India which are processed by Rare Earths. Out of these thermal applications materials have been provided to Defence and BARC. Though the Rare Earths have offered finished material like phosphorous catalyst, etc, to the civil industry for exploitation, it has not found much success. There are few mining sites with limited mining capability, hazardous residue, long gestation period, highly capital intensive, due to economy of scale and low consumption. Most materials are highly radioactive and, hence, need high order of safety measures in their handling.

Dr Kingsuk Mukhopadhyay, Scientist G, DMSRD, DRDO spoke on Smart polymer, fibre & fabrics for stealth, extreme cold, fire resistant & ballistic protection. One of the major challenges for portable water filtration is rate of filtration due to insufficient gravitational pressure. A mitigation technology in compact area is developed by DMSRDE using porous nano fibres which don’t use any chemical or electrical power for purification.

DMSRDE has prepared unique SSG which shows the change in viscosity as a function of shear force and holds a great promise for damping and shock energy dissipation. Besides this DMSRDE has successfully developed modular Bullet Proof Jackets (BPJs) to provide 360-degree protection as per the laid down GSQR.

Functional Materials for Radar Absorbers are Dielectric materials which impart dielectric polarization losses whereas Magnetic materials Imparts magnetic losses Ferrites, carbonyl iron, iron silicide. He also informed the audience about the development of Camouflage Systems, Synthetic Camouflage Net for Snow Bound Area (SBA) & green belt area produced and supplied to army. Radar Absorbing Camouflage Net (RSCN) were found effective against Visual, IR and Radar Surveillance. Multi-Spectral Camouflage Net (MSCN) effective in Visual, NIR, TIR and MW bands, Multispectral Personnel Camouflage Equipment and Mobile Camouflage System (MCS) have been developed.

DMSRDE successfully developed Boot Anti Mine Infantry (BAMI) for Infantry troops Indian Army and CAPFs.

Other equipment developed by DMSRDE includes NBC Suit Permeable, NBC Gloves, Advanced Chemical Protective Gloves, CBRN Overboot, NBC Facelet Mask.

Dr Apurba Sinhamahapatra, from CSIR-CIMFR, Dhanbad extensively covered Shaped Memory Alloys as the smartest materials, known for their unique ability to recover their original shape after undergoing deformation making them useful for precise and reversible shape changes. The alloy called Nitinol named after Nickel-Titanium Naval Ordinance Laboratory, displayed the ability to return to a predetermined shape after being deformed when exposed to heat. It has found greater applications in the medical devices, including vascular stents, guide wires, and orthodontic devices. Currently, its applications have gone beyond medical to include aerospace, robotics.

He also gave details on types of Shaped Alloys – One Way alloy which remembers only one shape. The other remembers two different shapes, one at a lower temperature and other at a higher temperature. Iron and copper based SMAs such as Fe-Mn-Si and Cu-Zn-Al are commercially available and cheaper than NiTi. High strength and lightweight material like Nitinol is known for its high strength-to-weight ratio, making it suitable for various engineering applications.

KNS Pavan Kumar, Scientist B, YSL-Smart Materials, DRDO covered the topic of Applications of Smart Materials for Future Military Electronics Applications. He spoke about

- Actuators and Adaptive Structures

- Deployable Structures

- Aircraft Components

- Space Mechanisms

- Satellite Components

- Aircraft Engine Components

- Self-Repairing Textiles

- Enhanced Load-Bearing Equipment

- Adaptive Camouflage Cloaks

- Biomechanical Support Systems

- Adaptive Control

- Morphing Wings of Aircraft

- Deployable Structures

- Temperature -Responsive Uniforms

- Bulletproof Vests with Shape Memory Properties

- Application in Drones

- Energy Harvesting for Extended Flight Time

SESSION 5 – ADDITIVE MANUFACTURING AND 3D PRINTING

The session was chaired by Dr Murugaiyan Amirthalingam, Associate Professor, IIT Madras. He gave a basic explanation of the concept of ‘Additive Manufacturing’ to the audience. He said that since Additive Manufacturing (AM) and 3D Printing Technology industry were still in nascent stage, it was the right opportunity to take the lead. He mentioned possibility of adapting additive manufacturing and 3D printing for engineering and biomedical applications, automobiles, etc, in addition to defence. He brought out the benefits of metal additive manufacturing in terms of material and energy saving and design freedom and its attributes of being a fully automated operation with limited skilled manpower requirement to realise from digital to physical form without any part-specific tooling requirements. However, he said that the existing “print-ready” alloys cannot cater to the diverse and growing needs of metal AM, especially in the defence sector, and that true benefits of metal AM can only be realized by developing more AM-friendly high-performance alloys.

V Srinivas, Scientist E, DMRL, DRDO spoke about Additive Manufacturing of Metallic Components for Defence Applications. He started by explaining the concept of Metal Additive Manufacturing. He brought out the advantages of metal additive manufacturing in defence sector specifically reduced product development lead time, reduced dependency on supply chain, manufacturing of critical components with complex geometric profiles, Optimized designs for weight reduction and reduced assembly of parts, manufacture of multi-material components and manufacture of parts with enhanced functional properties and performance.

He gave examples of additive manufacturing being done in the field of aviation and aerospace by GE, Airbus, P&W and NASA. In India, some components for the IAF have been manufactured using AM which have subsequently been certified by CEMILAC.

Today, DMRL is working on the design of new super alloys (alloys by design – ABD) using AM and on developing a test methodology for all the processes.

Capt (Dr) Nitin Agarwala, Senior Fellow, CENJOWS covered the aspects of 3D Printing for Ship Repairs. He began by explaining what AM is and then indicated how AM was slowly being introduced in the maritime sector. For ships, while the US and the US Coast Guard have installed printers onboard, they have used them to print small parts. He showed the cost advantage achieved and that the product manufactured was limited to a non-load bearing member as load bearing members required classification approval process which was still to be defined. He said that since AM had merit and was a sure way to encourage a circular economy, its acceptance would require more work but was a future technology for use on board ships.

Ram Kumar Krishnan, from Intech Additive Solutions covered the subject of Metal Additive Manufacturing through Ultrasonic Atomisation Technology. He indicated that powder quality, handling, purity and manufacture was a challenge for the industry for which Intech had developed solutions. He indicated that while there were a large number of metals, only 50 of them had been atomized to date and small MOQ (minimum order quantity) was a hold point for atomizing more metals. In this effort of manufacturing metallic AM powders, Intech has collaborated with a Polish firm Amazemet and was using ultrasonic atomization, which is considered the best process of manufacturing atomized metallic powder for AM.

S Murali Shankar, Managing Director, Super Auto Forge, covered the subject of Application of Additive Manufacturing in Industries. He provided an insight on manufacturing cold forged parts which is his company’s strength area for the last 50 years. Recently, they have moved to AM wherein they are manufacturing warm forging tools using AM. Such parts can be now manufactured in 78 hours as against 4-6 weeks required in conventional manufacturing process. The printed part has a greater life as internal cooling has been provided to the forged tool. He mentioned that the main challenge in AM is the cost of powder, reducing the build time of parts, increasing productivity and the need for post processing.

The last speaker Sachin Suramwar, from Gasptops briefed the audience on Metal Scan (on-line oil debris sensor providing real-time health monitoring of bearings and gears), Blade Monitor (on-line sensor mounted on engine fan case providing full-time/ real-time detection of blade distortion or cracking) and Chip Check (automated chip detector analyser deployable at the flight line/ maintenance bay) for monitoring equipment health.

Concluding Remarks. Lt Gen Sunil Srivastava, Director CENJOWS summarised the key takeaways of the seminar where he highlighted the need to finding indigenous solutions to the services’ specific requirements urgently in order to overcome the challenges faced in customising the hardware sourced from abroad in preparing the special matreials for defence usage. He said that we need to have a long term strategy in maintaining the assured supply of special materials during war and peace.