A Masterpiece of DRDO Design

The future battlefield is going to be dominated by technological advancements in weapon systems to gain superiority over the adversaries. The 155mm/52-calibre has become a standard calibre and is the backbone of artillery gun systems, since it provides higher range, lethality and longer range. The performance of the existing medium gun systems in the Indian Army in terms of range, accuracy and mobility was considered adequate to meet the earlier battlefield environment. In the changed battlefield scenario, where weapon locating radars and satellite surveillance provide better information about the targets, the towed artillery has to be extremely mobile and will have to conduct mission firing in a very short time. Therefore, shifting of firing position, quick redeployment and firing first salvo effectively in the shortest time has become imperative. All these requirements have compelled designers/users to upgrade the performance specifications of 155mm/52-cal gun. In addition to the towed gun system, the 155mm/52-calibre can be adapted for various mounted gun platforms such as Wheeled Gun System, Tracked SP Gun System and Truck Mounted Gun System.

The future battlefield will be characterised by short and intense engagements, nonlinear battles, simultaneity of operations, increased battlefield transparency, integrated and coordinated employment of all fire power resources including precision and high lethality weapon systems in a hybrid warfare environment. This further emphasizes the need to deploy long reaching guns, further enhanced with precision and accurate firing to disrupt the enemy’s preparations and destroy his build-up of forces even before he can launch an offensive.

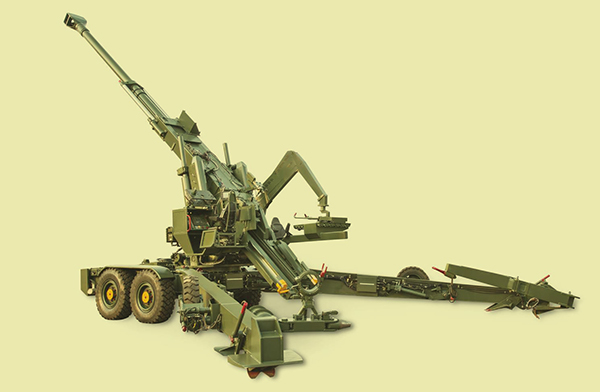

Futuristic Battle Winning Artillery Platform

Considering the current and imminent battlefield environment, advanced operational specifications of 155mm/52-cal Advanced Towed Artillery Gun System (ATAGS) has been evolved. These were based on operational requirements of the users and the vast experience gained in handling/firing of a current inventory of 155mm, 130mm and 105mm field guns. The study of contemporary 155mm/52-cal artillery guns and exhaustive system engineering studies including ballistics, target analysis and launching platform stability, transportability studies provided wealth of information/ data. All these inputs have been used to arrive at the appropriate specifications for the new system. The transformation of the operational parameters into the system and subsystem specifications is a complex task, since most of these parameters are inter-dependent and arriving at an optimum parameter is challenging. Finalising a technical specification for various subsystems is arduous, since inputs for achieving these inter-dependent parameters within the other constrains such as manufacturability, ease of assembly and minimum cost, etc., could not be realistically available.

Industry Participation

Armament Research and Development Establishment (ARDE), a nodal DRDO laboratory for weapon development, undertook the ATAGS project. The detailed configuration/options and system specifications were finalised based on the overall system engineering carried out by the team at DRDO along with preparation of virtual CAD model of the overall ATAGS with four-wheeled backpack configuration and also selection of various advanced sensors fitment such as Land Navigation System, Electro-Optic Sight and Muzzle Velocity Radar. The task of development and manufacturing of a gun system was offered to Indian industry in the form of work packages based on their knowhow, competence, experience and infrastructure. Bharat Forge Ltd (BFL) and Tata Power SED had taken up the role of co-developer in design development and manufacturing of the complete system, thus, realizing the total gun system encompassing gun structure, automotive portions, gun control and automation, with Bharat Forge Ltd taking the role of manufacturing gun barrel. Additionally, ARDE along with BFL developed and realised one Battery Command Post.

ALSO READ: Army Modernisation : Indigenous ATAGS vs Imported ATHOS

Two prototypes have been developed and have been test fired at different test firing ranges under all possible conditions to realize the unflinching reliability and stability of the gun system. The systems have been tested in high altitude at Sikkim Field Firing Ranges in sub-zero temperatures with commendable results and now are ready for user trials.

Developing both the software and hardware for the programme, as part of development of an advanced gun manufacturing facility, was the real challenge. It is professionally very satisfying that the entire gun has been conceptualised and created from the drawing board to being a fully functional weapon platform in India under the aegis of DRDO and ARDE.

Two private manufacturers being partners in the DRDO programme is also a first in India. Both companies have contributed to the program by involving their team of designers and engineers, who have designed various systems with their combined competence and experience in manufacturing technologies, quality control system and process control systems, which proved to be a crucial in the development. The existing quality related processes has made ATAGS reach a new level of excellence amongst similar weapon systems.

Complete hand-holding of the development partners starting from handing over of the first virtual CAD model to the design calculations followed by establishing the quality parameters in manufacturing was done by DRDO and ARDE, in particular. The team of engineers, who have handled complex tasks, had to assimilate and absorb the armament technology. A core team of 40 engineers, with experts across verticals like metallurgy, material science, mathematical modelling, servo-electrical, hydraulics, electronics, etc, worked steadfastly to design and develop ATAGS. This was commendable work which has been completed in a record time of three years.

With successful firing trials, both industry partners have become reliable development partners with full capability in design and manufacture of 155 mm gun systems. The competence and capability, along with infrastructure, has provided the company confidence in being able to participate in the on-going “Make in India” initiative.

DRDO’s initial requirement was for two ATAGS prototypes. The gun barrel and breech mechanism in of both the guns have been developed and manufactured by Kalyani Group. Special mention must be made of the futuristic and technically superior breech with higher service pressure developed by the Group and incorporated in the gun, which can withstand a pressure of up to 560 MPa. As a result of the continuous R&D efforts, strict quality control and complete understanding of the manufacturing process of a gun barrel manufacturing undertaken by Bharat Forge Ltd, the gun barrel developed for ATAGS, was found to be first time right when it was successfully proof-fired in Jun 2015 at CPE, Itarsi. The gun system was then successfully fired in December 2016 at PXE, Balasore. Such was the impact and success of firing that MOD instantly decided to showcase the ATAGS gun at the Republic Day parade in January 2017.

ATAGS has created a new world record by registering the longest ever distance of 48 kms surpassing the maximum ranges of 35-40 kms fired by any artillery gun in this category.

ATAGS is a perfect example of Public Private Partnership (PPP) model with DRDO. It is a benchmark system, which qualifies for ‘Make in India’ and will, in future, prove to be an asset to the Indian armed forces. It will be appropriate to mention some of the critical technologies, design/manufacturing knowhow gained during the development process.

ALSO READ: Artillery Technology India 2020 Seminar

• Design and Manufacture of Ordnance. This is the most critical element which has been established for the first time in the country by a private sector company. The forgings, heat treatment, autofrettaging, machining and rifling processes have been established with a great deal of engineering and fundamental science, which has always been the core strength of Bharat Forge Ltd. The ordnance was successfully proof-fired at extreme high pressure close to 568 MPa, which is the highest pressure recorded for any artillery gun systems in the world. This process required manufacturing of special steel and intricate knowledge of the metallurgy, which was also realised in-house.

• Gun with All Electric Servo Control Automation System & Ammunition Handling System. The super structure of ATAGS required in-house development of special welding techniques and tooling to establish the advanced manufacturing. An all-electric, ball screw linear actuator based system, which is highly reliable and accurate, is used for laying the gun, which is not available in the existing 155mm guns. It has additional advantages like close loop servo control, high positioning accuracy and operations from a battery bank. An automatic ammunition transfer system has been developed to transfer shell and charge into the gun barrel. These mechanisms are driven by a military grade 24VDC system and have three levels of redundancy and No-back technology is used for on field manual operation in case of emergency. This is an added advantage, since it provides truly “Silent Watch Operation”.

• Auxiliary Propulsion System (APU) and Under-carriage. An Advanced Electronic Steer by Wire system to provide best mobility in the world for towed guns, to synergize the shoot and scoot capability. The same was developed in-house by the industry partner, using all the resources available within the group. These drives endorse high-end dual redundant encoders with electronically controlled hydraulic pumps and traction motors. In-house developed axle for 4×4 drives provides independent suspension and articulation to mitigate toughest terrains. ATAGS can achieve speeds of more than 20 kmph in autonomous mode and above 70 kmph, while being towed by a Field Artillery Tractor.

• Software development and Gun Display Unit (GDU). ATAGS also offers an easy-to-operate graphical user interface, which is designed and developed in-house, based on various military and ergonomic standards that are required. This provides a simple but effective dashboard for displaying the information, operation of the gun and safety aspects.

Key Specifications of the Gun System

• Indigenously manufactured 155mm/52 Cal best-in-class artillery system jointly designed and developed by ARDE (DRDO) and supported by Industry partners.

• Futuristic and technically superior breech, with higher service pressure which can withstand pressure beyond 550Mpa

• Successfully test fired in India in all possible climate and terrain with temperatures ranging from minus 10 to +50, and achieved longest firing range of >48km (HE-ERFB BB) and >38km (HE-ERFB BT) in the 155mm family.

• Zero backlash electrical drives.

• Fully-automatic Ammunition Handling System (AHS).

• The system has ability to fire Zone 7 charge (BMCS).

• Rates of fire.

Burst: 5 rounds in 60 seconds.

Intense: 10 rounds in 2.5 minutes.

Sustained: 60 rounds in 60 minutes.

Present Status

The 155mm/52-calibre ATAGS has created a new world record by registering the longest ever distance of 48kms surpassing the maximum ranges of 35-40 kms fired by any artillery gun in this category. Most of the PSQR parameters including the stringent requirement of consistency and accuracy have also been achieved by ATAGS. The successful firing at various ranges with more than 1400 rounds having been fired without any hitch has proved that India can produce the best gun systems indigenously. The involvement of private industry with the DRDO at system level is a paradigm shift in PPP culture and has resulted in the realising of this state-of-the-art weapon platform in the fastest time frame. More such initiatives will help realise the vision of self-reliance and will give an impetus to Make in India. ATAGS is now ready and awaiting the user trials to again showcase its superiority against the available foreign gun systems.

[…] ALSO READ: ARMY MODERNISATION: The 155mm/52-cal Advanced Towed Artillery Gun System […]